Tube Settler Clarifier

Tube settlers are gravity settlers wherein the settler is provided with No. of inclined tubes to increase the surface area of separation of solids from the liquid.

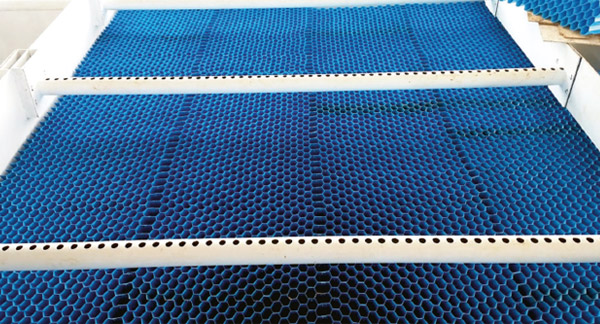

Tube settlers use multiple tubular PVC channels at an angle of 600, adjacent to each other, combined together to form a tube deck, for an increased effective settling area.

The flocculated water is fed into the feed basin, centrally located in the gravity settler.

The tube settler is characteristically provided with steep bottom hoppers.

Heavy flocs will settle faster in the hopper of the tube settler while the light particles enter the inclined tubes.

Due to a very low velocity of particles inside the tube and also due to the large surface area of the tube, the flocs agglomerates into the bigger size and slide down from the tubes into the hopper; this is then removed as sludge from the tube settlers.

As the units are provided with steep hoppers, there is no need to provide any sludge scrapping/ collection mechanism.

Sludge blow off is affected by the static head of water in the tube settler.

Sludge is withdrawn from the bottom of the Tube settlers as underflow and sent to the sludge sump for further de-watering process.

The clarified water is obtained as an overflow from the tube settler is sent for further treatment in sand filters.

Tube settlers are designed based on specific overflow rates and the settling velocity of the solids.

Applications

- Municipal and industrial water & wastewater treatment plants.

- Pre-treatment before rapid sand filters, activated carbon filters, and other polishing units.

- Clarification of surface water containing high turbidity and suspended solids.

- ETP/STP units for improved primary and secondary clarification efficiency.

- Retrofit and capacity enhancement projects where additional settling area is needed without expanding tank size.

- Sedimentation processes in chemical, textile, food, paper, power, and steel industries.

Key Features & Benefits

- Inclined tube modules (60°) that significantly increase the effective settling surface area.

- Low upflow velocity inside tubes, promoting floc agglomeration and improved settling.

- Steep hopper design eliminates the need for mechanical sludge scrapers.

- Modular PVC or PP tube decks for easy installation, replacement, and maintenance.

- Efficient sludge removal through gravity and static head pressure.

- Compact structure ideal for space-limited treatment facilities.

- Enhanced clarification efficiency with reduced hydraulic retention time.

- Lightweight and corrosion-resistant materials ensuring long-lasting performance.

- Cost-effective upgrade option for increasing plant capacity without major civil work.